Production

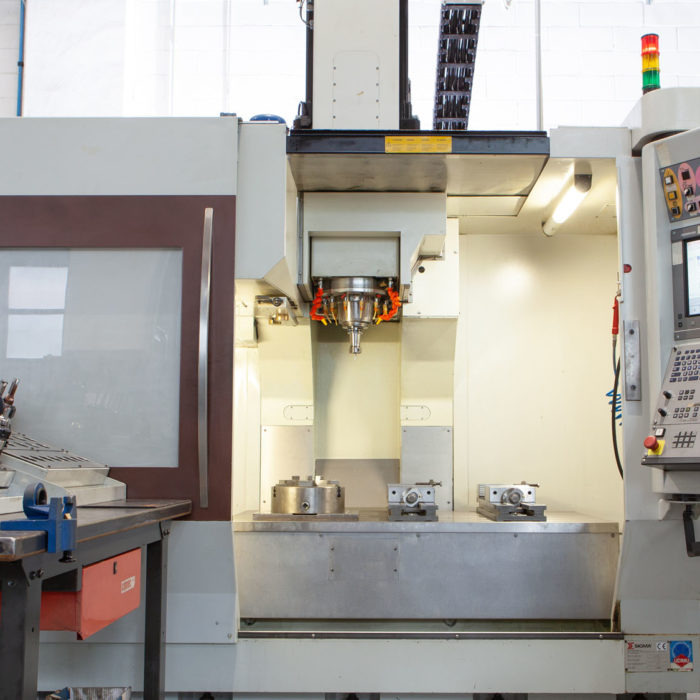

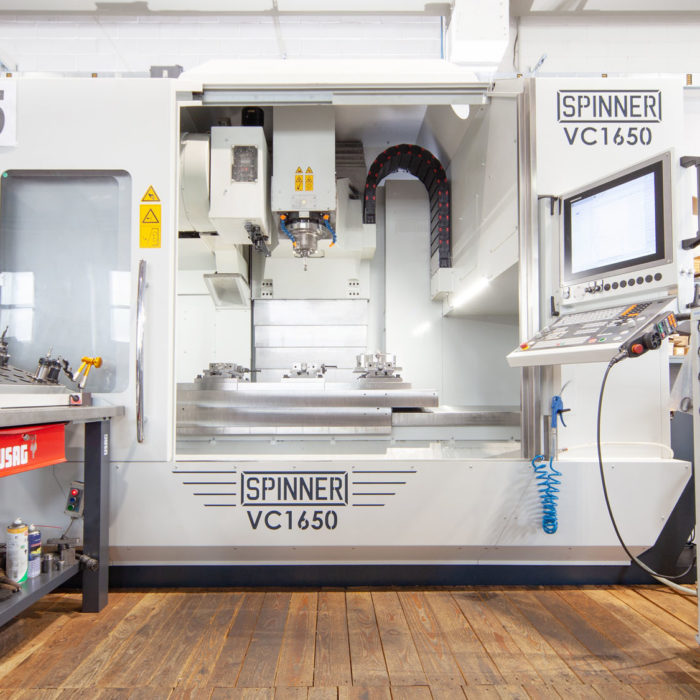

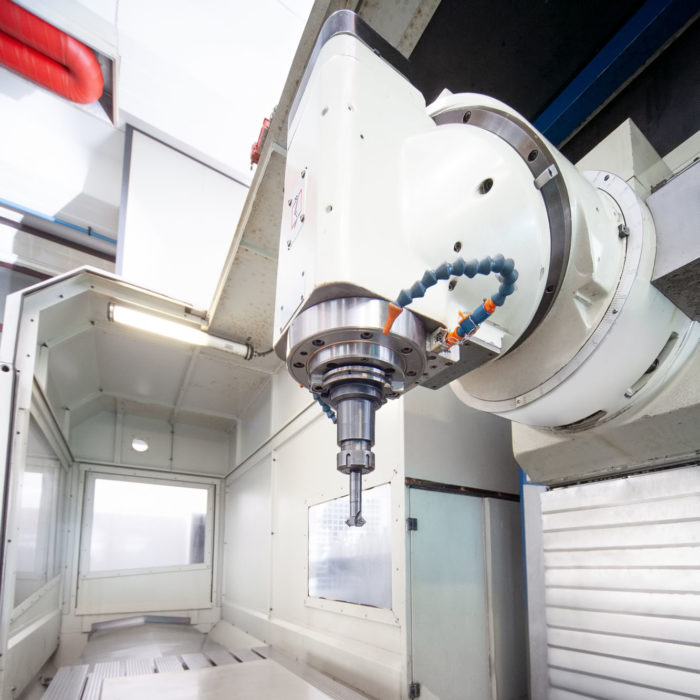

MILLING

G.L.B.Stampi is equipped with an internal department specialised in milling which, supported by the CAM department, performs all kinds of mechanical work: there are modern machines for the construction of moulds with different sizes and characteristics.

1 Spinner (new entry 2019)

1 Sigma

2 Tos

1 Sachman 4th axis 2500x900x1200

TURNING

1 OMG Zanoletti manual lathe

1 Doosan CNC lathe with motorised spindles

ELECTRICAL DISCHARGE MACHINING

G.L.B. Stampi has both die-sinking and wire-cutting electrical discharge machines in our electrical discharge department that allow us to complete our work

Wire erosion

1 Makino u6 (new entry 2018)

2 Fanuc IA

1 EDM die-sinker

To complete our machinery fleet we also have some traditional machines such as:

Delta tangential grinding machines

TCS mould testing machine

column drills

Bergonzi radial drill

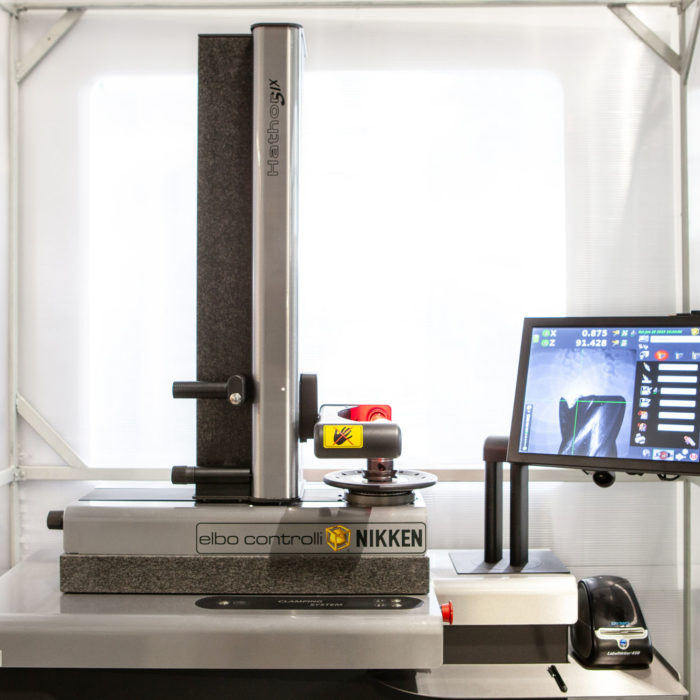

QUALITY CONTROL

Measuring machine: Tesa Micro-hite

HANDLING

10 tonne handling overhead crane

The machinery fleet includes milling machines and computer-controlled machines connected via the network to the CAM department.

The department’s machinery fleet undergoes periodic updates and extensions.